Does not apply

High Precision Automatic Micro Liquid Filling Machine Small Quantity Small Perfu

High Precision Automatic Micro Liquid Filling Machine Small Quantity Small Perfu

Couldn't load pickup availability

High Precision Automatic Micro Liquid Filling Machine Small Quantity Small Perfume Essence Oil Weighing Filling Machine

Description:

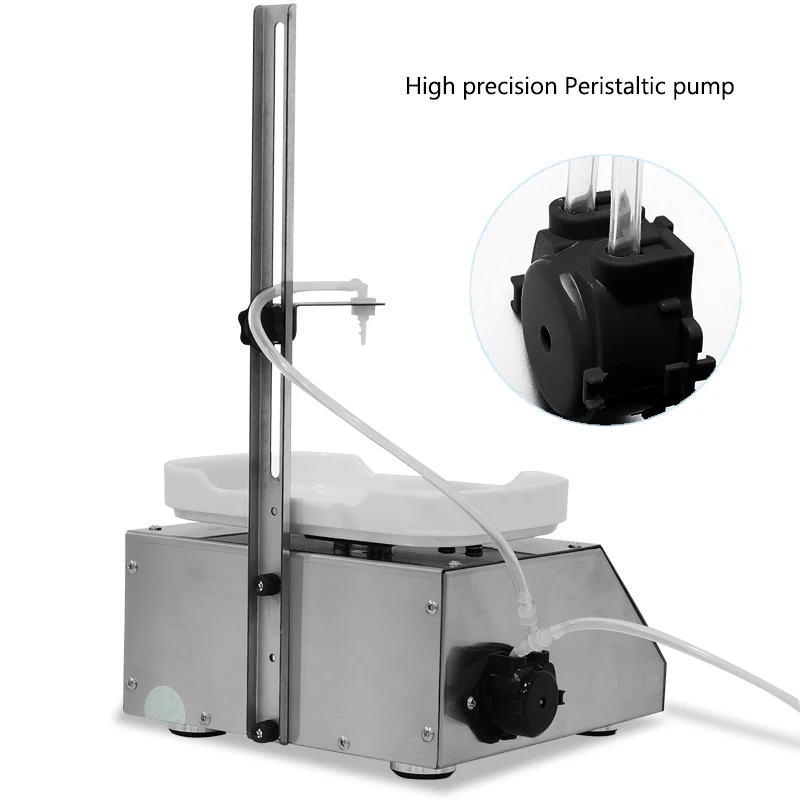

CSY-90M automatic frequency conversion micro-filling machine uses high-precision peristaltic

pump to work with frequency converter. After starting the filling, the pump first fills and fills at

the maximum flow rate, ensuring fast and efficient filling. When the filling volume is about to

reach the set weight, the inverter automatically slows down the pump flow rate, and when the

filling amount reaches the set weight, the pump is turned off to ensure the accuracy of the filling.

Specification:

Product model: CSY-M90

Rated voltage: AC 110V-220V

Rated power: 15W

Maximum flow rate: 100mL / min

Applicable capacity: 1-30mL (or 1-30g)

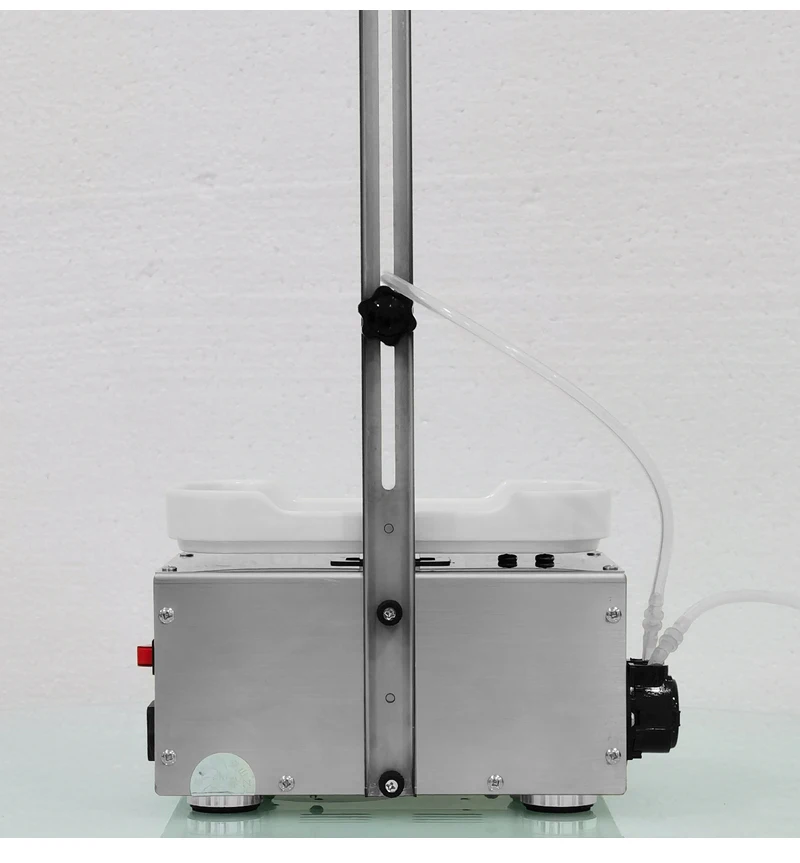

Filling height: adjustable from 1 to 15 cm

Filling error: 0.1g

Product size: 18cmX18cmX12cm

Machine weight: 1.65kg

Function:

1. Automatic peeling

2. Automatic start and stop

3. Automatic speed reduction

4. Automatic counting

5. Automatic reset

6. Data storage

7. Power failure memory

8. Delay adjustable

9. Automatic frequency conversion

FirstTechnical indicators

1,Power supply: The power outlet of the machine must be connected to the ground wire.

2,Display characteristics:Weight window 4 digits, Set window 4 digits, counter window 4 digits, trigger window 4 digits

3,Features:real-time weighing, overload alarm, automatic counting, automatic start, automatic frequency conversion, automatic stop, Filling data storage, delay adjustment, error correction,Return to factory settings and other functions.

4,Other indicators:

|

|

CSY-M10 |

CSY-M90 |

CSY-1200 |

CSY-3200 |

CSY-3500 |

Recommended filling |

0.05-10.0g |

0.5-10g |

2-100g |

5-1000g |

10-1000g |

Maximum weighing |

300g |

500g |

600g |

3kg |

3kg |

Graduation value |

0.01g |

0.1g |

0.5g |

1g |

1g |

Pump type |

Peristaltic pump |

Peristaltic pump |

Peristaltic pump |

Diaphragm pump |

Peristaltic pump |

Pump flow |

10ml/min |

90ml/min |

1.2L/min |

3.2L/min |

3.5L/min |

Display Unit |

g |

g |

g |

g |

g |

Rated power |

8W |

10W |

20W |

30W |

40W |

SecondThe display window and button function description

1,Display window:

Weight : displays the actual weight of the item being weighed

Set : User-set weight to be filled

Counter : number of bottles that have been filled

Trigger : the weight value that triggers the auto start

2,Button function:

[Man] : Enter manual mode

[Auto] : enter automatic mode

[Tare]: Peel and set to zero

[Set]: set the filling weight

[Trig]: set the trigger value

[Run]: manually start the filling function (click again to pause)

[Save]: store 4 groups of commonly used filling data

[M1-4]: Call the stored filling weight data

[ 0 ]: Counter value is cleared

The big green button and foot switch have the same function as the [Run] on the keyboard.

ThirdThe operating instructions

1,"Set " setting method:

Press the [Set] key to enter the value (e. g. , set 100g, enter 1 0 0), and then press [Set] again.

2,"Trigger" setting method: (trigger value can not be less than 3 grams)

Press the [Trig] key, enter the value (e. g. , set 35g, enter 3 5), and then press [Trig] again.

Note: The trigger value is set to empty bottle weight.In automatic mode, the automatic filling is triggered when the weight of the empty bottle exceeds the trigger value.

3,"Manual mode" operation method: (Press the [Man] key, the manual light is on, enter the manual mode;)

(1) Put the empty bottle, press the [Tare] button to remove the empty bottle weight, press the [Run] button to start the filling.The weight of the poured liquid reaches the set filling weight and stops automatically.

(2) Remove the filled bottle, put down an empty bottle, press the [Tare] [Run] button to start the next filling.

4,"Automatic mode" operation method: (Press the [Auto] key, the automatic light is on, enter the automatic mode)

Put the empty bottle, the system automatically peels and automatically starts filling after a delay of x seconds.When the weight reaches the filling weight, the filling is automatically stopped.Remove the filled bottle and the system will automatically reset to zero after a delay of x seconds.Put the next empty bottle and automatically start the next filling.

Note: When using the automatic mode, if the machine is not properly filled, it is because of a mistake caused by a cyclenot end yet.At this point, remove the bottle and press [Tare] to use it normally.

5,The setting method of"storing 4 groups of filling weights to M1-M4":

Press the [Save] key (the number of filling weights starts to flash), input the value to be stored, and finally press the [M1] key (the number of "filling weight" stops flashing) and the number to be entered is stored in M1. When you need to use the value of m1 as the filling weight, you can press m1 to set the value of m1 as the filling weight. (Set M2, M3, M4 as the method of setting M1)

6,How to cancel the automatic peeling function :

Restart the machine, press the [Auto] button, and then hold down the [3] button until you hear the alarm sound of the machine and let go. At this time, the automatic peeling function has been cancelled. If you want to turn on the automatic peeling function, repeat the above operation. Once set up, the machine will remember forever.

7,How to set the "MID-RANGE DECELERATION RATIO":At a few percent of the set amount, it automatically goes to medium speed

Press [ auto ] , set the flow rate to a proportional value (e. g. , 80) , press the speed Knob long enough to let go when the "Beep"is heard.

8,How to set the "The value of slow down": (How many grams before the end automatically slows down)

Press [Trig] [Save],then enter the value to be set , and then press [Trig] again.

9,"factory settings" method: press the [ auto ] button, and then hold the [5] button not to let go, until the machine alarm "beep" after the release. The machine is back to factory status.

FourthAbout flow rate regulation

1,This product with flow rate adjustment KNOB, speed 1-100 adjustable, and digital display flow rate value;

2,Rotating knob adjustment, the speed value will be digital display, no operation 3 seconds after the exit.

3,Press the KNOB, the flow rate value will display, can view the current flow rate value, no operation after 3 seconds exit.

4,Flow rate can be adjusted at any time, after the adjustment will automatically save, power-off memory.

FifthHow to use the set time method of filling

1, Press [ auto ] , long press [2] can switch to "the set time method of filling"(the same method can also be restored to "the set weihgt method of filling") .

2, The set time method of filling displays the number in seconds, accurate to 0.01 seconds.

3, Press [ settings ] , input filling time, press [ settings ] , you can set the filling time.

4, Press [ trigger ] , input interval time, press [ trigger ] , can set the interval time of automatic filling.

5, Press [ set ][ start ] , load to the amount needed, then press [ start ][ set ] , can extract filling time.

6, Automatic mode can be fixed interval between the automatic start, manual mode by pressing the start button to start.

SixthlyPoints to note

1,The user shall select a quantitative filling machine of suitable range according to the said products.

2,Please check its accuracy before use, otherwise the company will not be responsible for the loss.

3,The machine contains precision electronic scale, it is forbidden to be overweight.

4,The Height of filling head can be adjusted to about 10 mm from the bottle mouth.

5,When in use, please keep the machine level and stable to avoid big vibration or impact, otherwise it may cause damage.

6,Machine first use or long time no use, very few will not absorb water, because the pump internal dry result. You need to add some water from the intake pipe to the pump and then start the machine.

7,It is better to clean the machine with clean water after every use, which can prolong the service life of the pump.

8,When the machine is not in use, please empty the liquid and store it in a ventilated and dry place.

SeventhAfter-sales service

1,The product is guaranteed for 12 months from the date of sale.

2,Products with a warranty card, please keep the user properly, do not make up the loss, correction invalid;

3,Do not disassemble the machine, or it will be regarded as waiver of warranty.

4,Non-natural damages such as machine break, over weight crush, water damage, etc. are not covered by the warranty.

5,Due to the high purity of some liquid health requirements, the product can only be returned in the case of non-official use. After receiving the goods, please first use clean water for functional testing, sure no problem, then use for other solution filling. Once the machine has filled other liquids that are not clear water, it will no longer accept returns.